Cost Savings Through Manual Handling Safety – Why Prevention Pays Off

When businesses think about manual handling safety, the first thought is often employee health. While that’s the most important aspect, many employers overlook another major benefit: financial savings. Investing in safe manual handling practices not only protects workers but also saves companies thousands (and sometimes millions) in hidden costs.

Lorem ipsum dolor sit amet, consectetur adi

The Financial Benefits of Manual Handling Safety: Protecting Workers and Your Bottom Line

When businesses think about manual handling safety, the first concern is typically employee health. While that’s the most important aspect, there’s another critical benefit that many employers overlook: financial savings. Investing in safe manual handling practices doesn’t just protect workers—it also saves companies thousands (and sometimes millions) in hidden costs related to workplace injuries.

By understanding the true costs of manual handling injuries and implementing effective safety measures, employers can not only enhance worker well-being but also improve the financial health of their business.

piscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

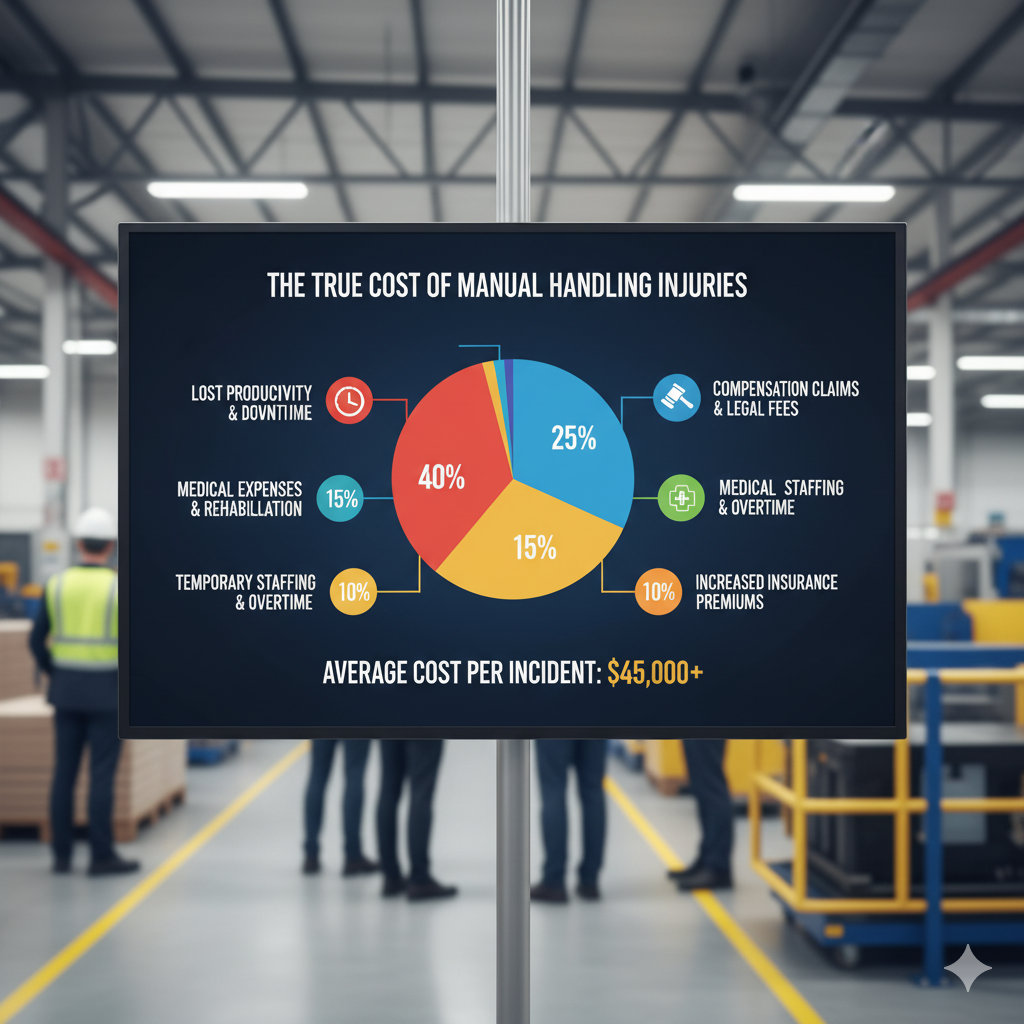

The True Cost of Manual Handling Injuries

Manual handling injuries are a leading cause of lost working days, compensation claims, and disruptions to operations. The financial impact can be far-reaching, affecting both direct and indirect costs. Here are some of the hidden costs employers may face:

1. Medical Expenses

The medical costs associated with manual handling injuries can quickly add up, including:

Surgery

Physiotherapy

Medication

These expenses not only affect the injured employee but also require time away from work for recovery.

2. Compensation Claims

Injured employees may file workers’ compensation claims, which can run into the thousands of dollars depending on the severity of the injury. These claims may also lead to legal fees and settlement costs.

3. Lost Productivity

When employees are injured, operations are disrupted, leading to a loss in productivity. Injured employees may take weeks or months to recover, leaving gaps in the workforce and delays in critical tasks.

4. Temporary Staff Costs

To cover for injured employees, businesses often need to hire temporary staff, which comes with added expenses.

5. Insurance Premiums

Higher accident rates generally lead to increased insurance premiums. Companies with frequent workplace injuries pay more for insurance, significantly impacting their bottom line.

How Safety Saves Money

By prioritizing manual handling safety, employers can achieve substantial savings across the board. Here’s how a proactive safety approach translates into cost savings:

1. Reduced Absenteeism

Safe workplaces lead to fewer injuries, which means employees spend more time at work and less time recovering at home. This reduction in absenteeism directly boosts productivity.

Example: Implementing safe lifting techniques and providing adequate equipment reduces strain and prevents injuries, keeping workers on the job.

2. Lower Compensation Costs

By reducing the frequency of injuries, businesses can avoid costly legal claims and settlements. Fewer claims mean lower premiums and fewer payouts, saving companies significant amounts in the long term.

3. Improved Productivity

When workers use proper manual handling techniques and have access to ergonomic equipment, they are more efficient and less fatigued. This improves overall task completion speed and reduces errors.

Example: A worker using a trolley to move heavy loads instead of manually lifting them will complete the task more quickly and with less effort.

4. Lower Staff Turnover

Employees who work in safe and supportive environments are more loyal and less likely to leave. This reduces the costs associated with recruiting, onboarding, and training new workers.

Example: Workers in safer environments are more satisfied and less likely to seek employment elsewhere, reducing turnover and retaining valuable skills.

5. Insurance Benefits

Companies with a strong safety culture and low accident rates may be eligible for reduced insurance premiums. Safe workplaces often qualify for discounts from insurers, reducing the financial burden of premiums.

Practical Steps for Cost-Effective Manual Handling Safety

✅ Risk Assessments

Performing regular risk assessments to identify dangerous tasks before they result in injuries is a cost-effective way to prevent incidents. Identifying high-risk tasks and modifying them can prevent costly injuries and legal expenses.

✅ Mechanical Aids

Investing in forklifts, trolleys, hoists, or conveyors is cheaper than paying for injuries. These mechanical aids can make manual handling safer and more efficient.

✅ Training Programs

Educating workers on safe manual handling techniques is far more cost-effective than dealing with long-term compensation claims. Regular training can help employees develop proper lifting techniques and prevent unnecessary strain.

✅ Safety Culture

Encourage employees to report unsafe practices early and make safety a part of your company culture. The earlier unsafe practices are identified, the easier it is to prevent costly accidents.

Case Example: Logistics Company

A logistics company was facing high workers’ compensation claims due to frequent injuries related to manual lifting. After investing in lifting equipment (forklifts and pallet jacks) and implementing refresher training, the company reduced its annual injury claims by 40%. The initial cost of equipment and training was recovered within two years due to lower insurance premiums and reduced absenteeism.

Conclusion

Manual handling safety is not just about compliance—it’s a smart financial decision for any business. By investing in proper equipment, training, and risk management, businesses can save money, boost productivity, and ensure a healthier workforce. The initial investment in safety practices pays off through lower costs, higher employee morale, and a better reputation in the market.